Nature-Inspired Gel Explains Why This Duck Is Stuck

Today this material can seal pipes and brave the ocean. But someday it could be used in surgery or underwater repairs

A rubber duck glued to a rock by the sea using one of the researchers’ hydrogels.

Hailong Fan and Hongguang Liao

On the shores of a beach in northern Japan, waves pummel a rubber duck stubbornly stuck to a rock. Thanks to a new supersticky hydrogel lining its base, the toy won’t budge.

Hydrogels are soft, jellylike materials used in many fields. In medicine, they can dress wounds and deliver drugs. In agriculture, they can help soil hold more water. But making substances sticky is tough—and underwater, it’s even tougher. The glues typically don’t hold well under a wet and salty surf.

Researchers plastered a new superadhesive hydrogel on the base of a rubber duck and propped it on a rock by the ocean. The duck may stick their for years, the researchers say.

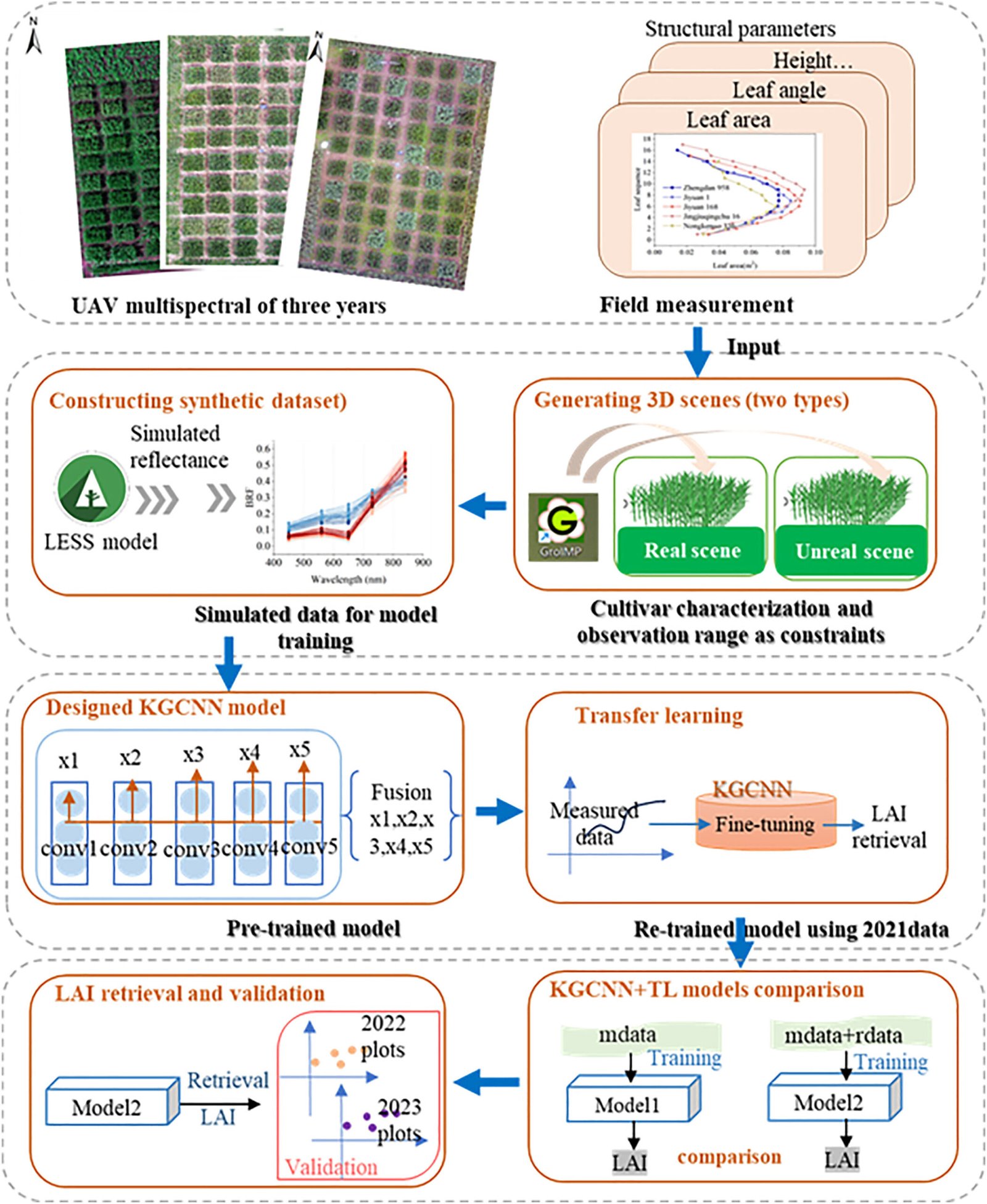

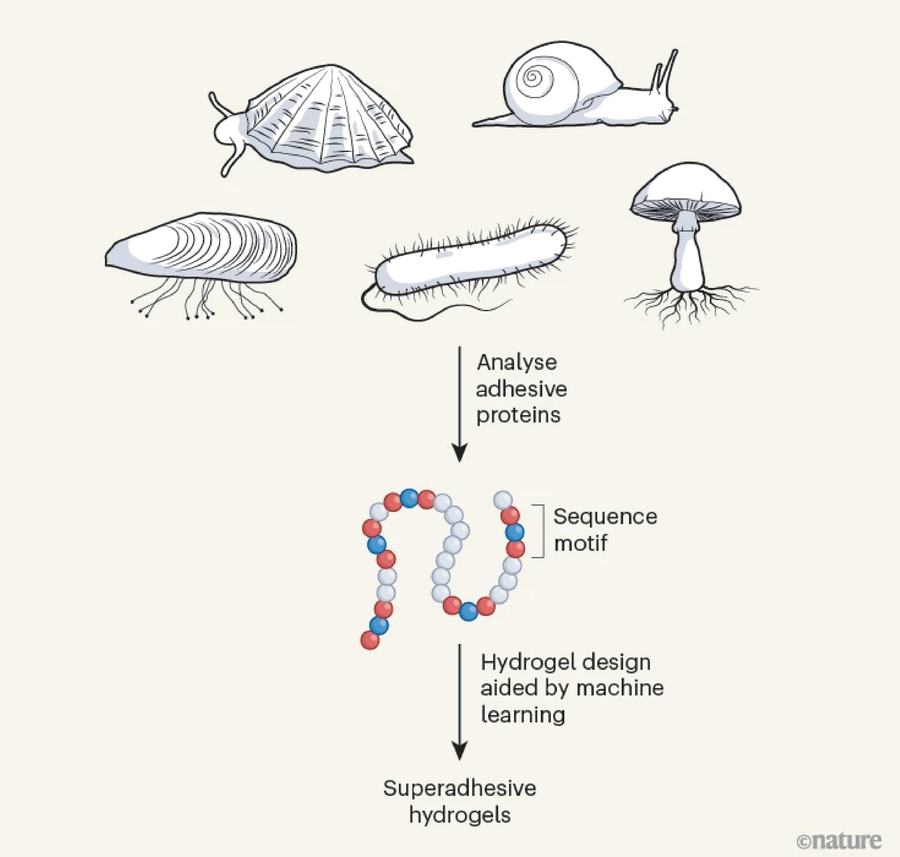

Nature, however, has a solution. Creatures such as barnacles and mussels naturally produce proteins that let them stick to wet surfaces. Inspired by these adhesive abilities, researchers combed through catalogs of these animals’ protein structures to mimic their stickiest features. Then, the scientists incorporated these protein structures into the hydrogels and tested them. After running several experiments, the team fed the results to a machine-learning system so that it could design a hydrogel with even stronger glue. The system came up with three superadhesive designs, composed of different protein structures, which the researchers described this week in Nature.

On supporting science journalism

If you’re enjoying this article, consider supporting our award-winning journalism by subscribing. By purchasing a subscription you are helping to ensure the future of impactful stories about the discoveries and ideas shaping our world today.

Jonathan Barnes, a polymer scientist at Washington University in St. Louis, who was not involved in the study, was impressed by the sheer strength of the enhanced hydrogels. In one experiment, the researchers used one of the gels to glue together pairs of plates made of one of three different materials—ceramic, glass and titanium—in a tank of saline. Each glued pair had a kilogram-mass load suspended below it. The gel held on for more than a year. “To last for a year is incredible,” Barnes says.

Researchers analyzed the amino acid sequences of naturally occurring protein glues used by organisms to adhere to wet surfaces. They identified characteristic sequence motifs that were then used to inform the design of adhesive hydrogels, with machine learning employed to optimize the designs. The authors thereby identified superadhesive hydrogels that function well under water and that could have applications in surgery and tissue regeneration and as materials for use on ships and offshore structures.

Nature; Source: “Data-Driven De Novo Design of Super-Adhesive Hydrogels,” by Hongguang Liao et al., in Nature, Vol. 644; August 7, 2025 (reference)

All three of the artificial-intelligence-designed hydrogels showed similar strength in artificial seawater. But one outperformed the others when tested in deionized water, which is devoid of charge and not found in nature. The differences in strength show that some adhesive materials may be more equipped for specific environments than others. “We are now working to tune this difference and test them in different conditions,” says study co-author Jian Ping Gong, a polymer scientist at Hokkaido University in Japan. “We also want to improve and [find] other formulations that can work on metal, for example.”

After synthesizing the ultrasticky gels, the scientists took two of them into the field to test their real-world capabilities. The researchers used one gel to seal a hole at the base of a three-meter-long pipe that was filled with tap water to simulate a high-pressure water leak. And they used the other to affix a rubber duck onto a rock to see how well the technology fared in seawater. One day these gels could help researchers develop artificial skin or repair underwater and offshore structures.

“[The study] points to tougher, faster and more reliable wet adhesives—for medical sealing, marine infrastructure and emergency repairs,” says Ximin He, a materials scientist who studies biologically inspired materials at the University of California, Los Angeles, and was not involved in the paper. “The data‑driven playbook they use could shorten the path from idea to material across many applications that affect daily life.”