A team of chemists is pioneering a new approach to creating plastics made from whole-cell algae and common chemical components. These biohybrid plastics are strong, highly adaptable, and fully recyclable.

The first plastic-like materials were created from natural substances but were quickly replaced by petroleum-based plastics. These plastics were inexpensive to produce and boasted superior properties such as high durability. Now, their poor recycling ability has led to a mounting environmental crisis, causing scientists to rethink the plastics industry and turn back toward creating biomass-based plastics, or bioplastics.

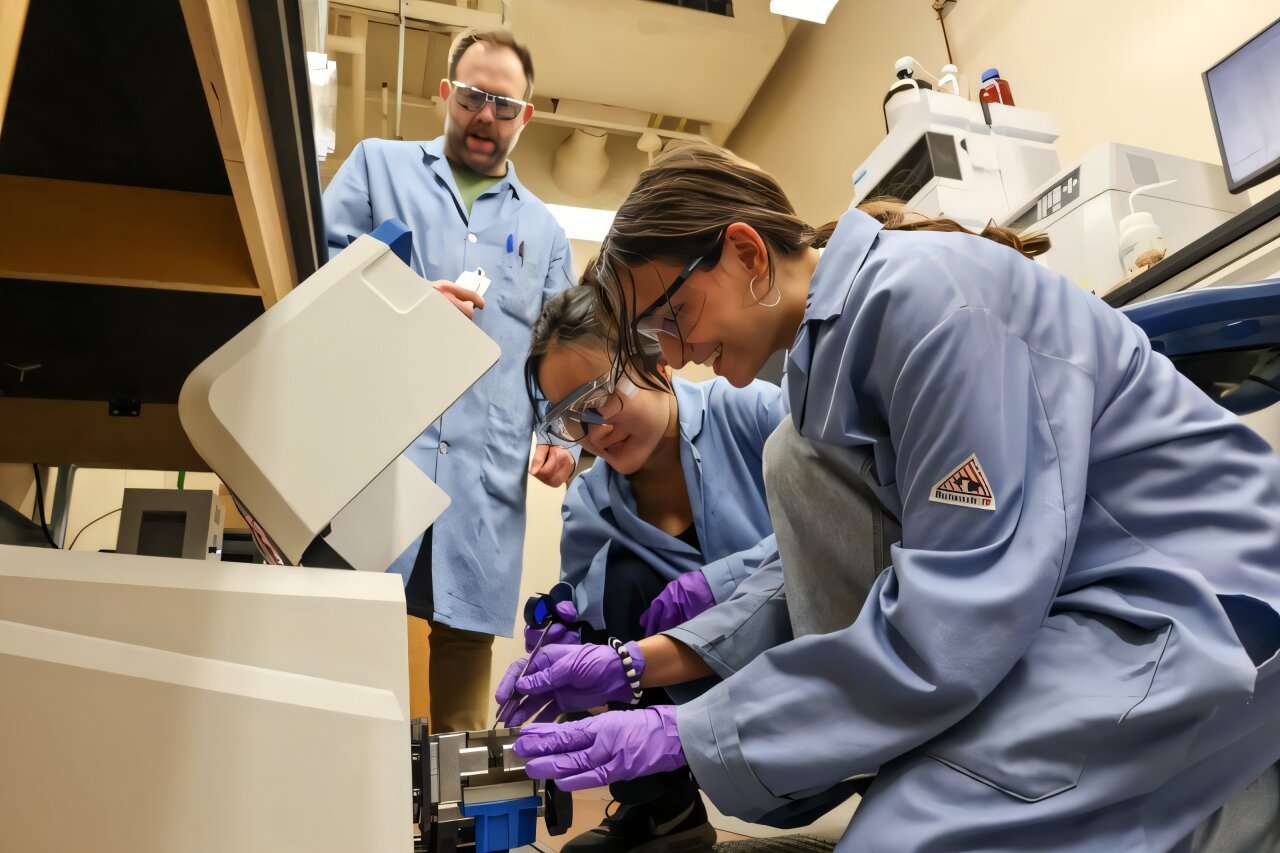

To tackle this crisis, Assistant Professor Josh Worch and his team invented a new strategy to enhance the renewability and recyclability of plastic materials without compromising their performance. They combined unprocessed biomass, in this case algae, with common chemical components in a ball mill to make tough biohybrid plastics.

The key to creating the robust material is what’s called a mechanochemical synthesis strategy, which the team described in a recent study published in Angewandte Chemie.

The synthesis strategy came from a moment of “serendipitous science,” as Worch put it. The moment the team threw all the algae material and chemical components into a ball mill, which is a high-energy mixer, the story changed.

-

Emily Bird (at left) and Meng Jiang look at algae collected from the Duck Pond. Credit: Spencer Coppage for Virginia Tech.

-

A sample of the Worch lab’s new, fully recyclable biohybrid plastic. Credit: Spencer Coppage for Virginia Tech.

The ball mill technique shortened the plastic synthesis from two days to just 1 1/2 hours and allowed the biomass to integrate with the synthetic parts of the material, making it a hybrid plastic. It is also a potentially scalable process because milling equipment is commonly found throughout many industries.

“It’s an extremely simple process, making it a very efficient way to create plastic,” said Emily Bird, an undergraduate student who co-led the work along with Meng Jiang, the lead graduate student on the project.

In the plastics world, ball milling is typically used to grind materials down into finer pieces. In a first, Virginia Tech researchers are using it to build more sustainable plastics.

Team members designed the hybrid plastic to include a type of whole-cell algae, known as spirulina, because it is inexpensive and widely available. They also surveyed other types of biomass resources, including agricultural waste left over from crop processing.

“This is one of the most exciting parts of our ball milling approach, since we believe the technique is generalizable to many different materials,” said Worch.

Complete recyclability

The new hybrid plastic is both robust and highly adaptable. It can easily be remolded into new shapes or even completely broken down. The team can separately recover the algae and chemical components in the hybrid plastic to be used again.

“These features make the plastic highly versatile, ensuring that it does not end up as waste itself,” said Jiang.

More information:

Meng Jiang et al, Mechanochemical Synthesis of Recyclable Biohybrid Polymer Networks Using Whole Biomass, Angewandte Chemie International Edition (2025). DOI: 10.1002/anie.202510449

Provided by

Virginia Tech

Citation:

From pond to polymer: Chemists create fully recyclable plastics using whole-cell algae (2025, August 5)

retrieved 5 August 2025

from https://phys.org/news/2025-08-pond-polymer-chemists-fully-recyclable.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.